High Temperature Chlorination Solar Panel Recylcing

Recycling of copper indium gallium diselenide cigs solar cell materials is important to ensure future supply of indium and gallium.

High temperature chlorination solar panel recylcing. High temperature chlorination and solvent extraction was also tested for separation of copper indium and gallium. Industry experts who have been following developments of end of life solar panel management recently provided an update on solar panel recycling in the u s. Trichlorosilane is then heated to a much higher temperature 1150 degrees c 2102 degrees f at which point it decomposes. Irradiance of 500w m 15 c module temperature zero wind speed and air mass am of 1 5.

Solar photovoltaic panels whose operating life is 20 to 30 years lose productivity over time. In the proposed chlorination process the residue obtained after the separation of selenium is introduced into a furnace at the required reaction temperatures which are 260 and 340 c for gallium and indium respectively. The international renewable energy agency estimated that there were about 250 000 metric tons of solar panel waste in the world at the end of 2016 and that the figure could reach 78 million metric tons by 2050. 5 so to be financially worthwhile the total cost of recycling a stripped solar panel would have to be less than roughly 8.

As no one is offering to pay for old solar panels or even take them off people s hands for free we can be pretty sure no one has worked out how to do this. By 2050 the united states is expected to have the second largest amount of end of life solar panels after china. The lifespan of solar panels may thus be much longer than officially stated. Our previous work includes recycling of selenium from cigs materials and a scoping study on high temperature chlorination for the separation of the remaining elements using different chlorination agents.

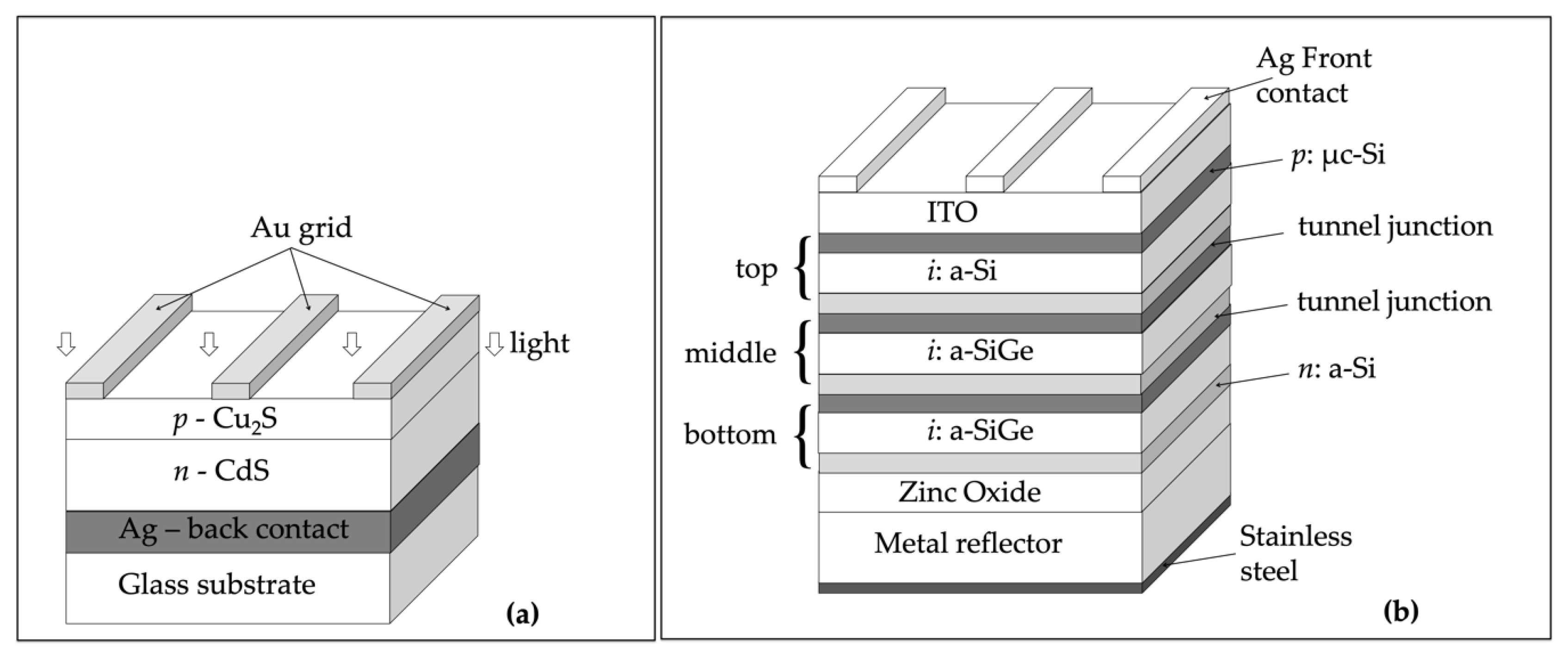

As stated above there are presently three different types of recycling process applied to solar pv panels which are physical thermal and chemical as illustrated in fig. The high temperature chlorination is a separation method relying on the treatment of a material rich in metals with a chlorination agent at high temperatures to form volatile metal chlorides. Solar panels contain lead cadmium and other toxic chemicals that cannot be removed. One of the products of its decomposition is very pure silicon.

Recycling solar cells cigs pyrometallurgy hydrometallurgy. The solar panel testing parameters are defined as follows. From a regulatory aspect pv panel waste still falls under the general waste classification. During the sustainable materials management smm webinar shining the light on solar panel recycling.

However electrochemical separation and was determined to be the promising separation method for future process development. This comes to a total of 8 15 per panel. In contrast to high temperature conditions htc testing the low temperature conditions ltc test the performance of solar panels under low irradiance and temperature levels. Download high res image 352kb.

Disposal of solar panels.